Brewing Down to a Fine Art

How We Make Our Beer

We’ve been brewing König Pilsener in Duisburg-Beeck in western Germany since 1858. Our long-standing tradition and attention to detail have made our beer what it is today: a pilsner of the highest quality with an unbeatable taste. Read on to discover exactly how König Pilsener is made and how it finds its way from our brewery to you.

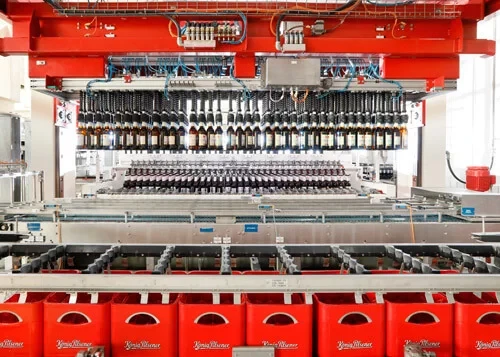

Our Brewery

An exceptional beer to savor the moment – brewed to perfection using a combination of traditional methods and the latest technology. König Brewery in Duisburg-Beeck in western Germany is one of the country’s best-known breweries and has been making König Pilsener since 1858.

The World’s Oldest Food and Drink Law

The German Beer Purity Law was introduced by the Bavarian Duke Wilhelm IV in 1516. It continues to dictate how beer is produced in Germany to this very day, making it the oldest surviving food and drink law in the world. It is a cornerstone of the Bitburger Brewery Group’s commitment to producing brews of outstanding quality.

Specially Selected Ingredients to Ensure Consistent Quality

The Bavarian Duke Wilhelm IV brought in the German Beer Purity Law on 23 April 1516 to establish a consistent level of brewing quality and to prevent dangerous experimentation. The law stipulated that beer could only be produced from water, malted barley, and hops.

The Importance of Yeast

Yeast’s essential role in beer fermentation was not understood when the law was first introduced. Instead, it took until the 19th century for the importance of this fourth ingredient to be recognized.

Brewing Without Additives

Beer from the Bitburger Brewery Group has always been free from artificial flavorings and additives. Even as modern brewing techniques developed, the Bitburger Brewery Group has remained true to the ingredients prescribed by the German Beer Purity Law. The Group believes in preserving the unique, natural taste that only these ingredients create.

Protectors of the German Beer Purity Law

The German Beer Purity Law is recognized worldwide as a sign of superior beer quality.

Our Ingredients

Carefully Selected Barley

We only use the golden-yellow grains of the best barley in our beer. The barley is malted to allow its starch to be converted into sugar during brewing.

Aromatic Hops

Our hops give König Pilsener its mildly bitter taste. So crucial are they to our beer’s flavor that our master brewers searched far and wide to find the hops with the finest aroma. They struck it lucky in the German region of Hallertau, which has one of the country’s richest hop-growing traditions.

Pure Water

Another essential ingredient in our beer is pure, mineral-rich water sourced from Hohe Mark Nature Park, which is just 28 miles from our brewery. After subjecting the water to strict quality controls, we combine it with our hops and malt, drawing on our passion and years of experience to transform it into our delicious König Pilsener.

Menu

Menu